Blogs

Pipe Repair Kit for leakage

Even when water pressure cannot be shut off, the Pipe Repair Kit allows the operator to quickly and effectively mend a broken or leaky pipe in under 30 minutes. Any diameter pipe consisting of copper, PVC plastic, steel, stainless steel, malleable iron, GRP, ceramic, clay, concrete, lead, or rubber can be repaired. Pipe repair kits are employed in both home and industrial settings for large-scale pipe repairs. Since each device has been approved, drinking water pipes can be connected to them without risk. The Kit can be applied to pipelines transporting hot and cold water as well as chemicals and is pressure resistance up to 30 bar and temperature resistance up to 200oC. How to use a Pipe Repair Kit to stop a leaky pipe Superfast Epoxy Putty is used to plug the leakage in applications where the water pressure could be shut off. Taking the necessary amount of putty, mixing it by hand, and then pressing it into and around the break or hole in the pipe, which will harden as it cures to seal the break or hole, is how you use a Superfast Stick. Wrap & Seal Pipe Break Tape is applied to seal off live leakage. The silicone-based waterproof tape has a 300% stretch capacity. It melts into a solid rubber band when it is wrapped around pipes, offering a repair that is pressure-resistant. Benefits of a Pipe Repair Kit Without any prior experience, enables the user to perform an emergency repair and fix a leaking pipe in 30 minutes. Fixes live leakage, eliminating the requirement to turn off systems. Provides a cheap substitute for hiring a contractor or buying replacement components. Enhances the longevity, chemical resistance, and pressure resistance of pipes.

Di-Electric Silicone Grease

Silicone oil and a thickener are combined to create silicone grease, also known as dielectric grease, which is a waterproof lubricant. Amorphous fumed silica is most frequently used as the thickener and polydimethylsiloxane (PDMS) as the silicone oil. With this recipe, silicone grease is a transparent, viscous mixture whose precise qualities rely on the kind and quantity of its constituent parts. Fluorinated silicones or, for low-temperature applications, PDMS with certain phenyl substituents in place of methyl groups are used to create more specific silicone greases. Other thickeners, such as stearates and powdered polytetrafluorethylene, may be employed (PTFE). A hydrophobic, translucent silicone dielectric compound called silicone grease provides the best possible corrosion and water resistance. A layer of non-hardening dielectric paste is applied to both indoor and outdoor electrical wiring to seal, waterproof, lubricate, and insulate them. It offers ecological preservation without impeding connection or resulting in short circuits since it is electrically insulating but still permits current to pass through metal contacts. Additionally, it works well to lubricate and seal rubber and plastic components. Transformers, disconnects, switching mechanisms, electrical contacts, outdoor lighting, scoreboards, traffic lights, high voltage poles, spark plugs, battery terminals, fasteners, seals, gaskets, plastic insulators, and O-rings are all frequently utilized with silicone dielectric grease. In tough weather and marine situations, this silicone-based grease is helpful. Features & Advantages Appropriate for both high- and low-voltage applications Lubricates, seals, waterproofs, insulates, and Prevents corrosion Stops pitting and arcing A wide service temperature range between -58 and 482 °F (-50 to 250 °C) Resistant to temperature changes; does not harden, melt, bleed, dry, freeze, or separate. Safe for plastics and rubber

Contact Adhesive

A rubber-based adhesive form is called a contact adhesive, also known as “contact cement.” Rubbers, including polychloroprene, could be found in both natural and synthetic contact adhesives. When materials over which a contact adhesive has been placed establish contact, unlike removable adhesives, the bonding is permanent. Features of contact adhesives Liquid contact adhesives are accessible in water or solvent form. Although many contact adhesives sold as solvents are hazardous and combustible, they have the benefits of rapid drying and bonding. The contact adhesive needs to be placed on the two surfaces that need to be joined for it to function. Therefore, the contact adhesive cannot be used to connect the two surfaces immediately. However, the bonding should wait until the contact glue has dried. However, once the contact glue has dried, which can take up to 24 hours in some cases, the bonding procedure is often fairly quick. The two surfaces can be joined once the contact adhesive has dried. After the adhesive has cured, the bonding procedure can typically be completed in 30 minutes (and occasionally, even in less time). Since the bonding is permanent and repositioning is practically impossible, a high level of accuracy is needed. Due to this, only one or two of the contact adhesive-bonded surfaces can be separated from one another. Where do people utilize contact adhesives? In the woodworking business, contact adhesives are frequently used to attach laminate to other wood surfaces. They can also be used to put together furniture, countertops, or building panels.

Magnaflux Kit-Technical Beacons

The Magnaflux Kit is a complete system for detecting surface and near–surface defects in all types of metals. The kit includes a water–based fluorescent dye, a developer, a cleaner, and a magnifier. The dye penetrates surface defects and is then fluorescent under ultraviolet light, making them easy to detect. The developer creates a contrast between the dyed area and the rest of the metal surface, making the defects more visible. The cleaner removes the dye and developer from the surface, and the magnifier allows for close inspection of the defects. Some common applications for Magnaflux kit are: 1. The Magnaflux kit is used in non–destructive testing of welds by applying a magnetic field to the weld. This produces a magnetic flux that can be used to detect irregularities in the weld. 2. The Magnaflux kit is used to detect cracks and defects in metals. It uses a magnetic field to detect cracks and defects in metals. 3. The Magnaflux kit helps in checking the integrity of metal structures by using a special magnetic fluid to detect surface and subsurface cracks in metals. How to apply Magnaflux kit? There are many ways to apply Magnaflux kit, depending on the specific needs of the project. One common method is to apply the kit with a brush or a roller. Another common method is to apply the kit with a sprayer. There are several reasons to buy a Magnaflux kit from us as we have a proven track record of providing high quality products and excellent customer service.We are an authorized distributor for Magnaflux and carry a full line of their products.We offer competitive pricing and discounts for volume purchases.We have a knowledgeable staff that can help you select the right products for your needs.

How to use magnaflux spotcheck

Magnaflux, a leading manufacturer of non–destructive testing (NDT) equipment, offers a complete line of spotcheckers for magnetic particle testing. These portable, easy–to–use units provide a quick, reliable method for detecting surface and near–surface indications in ferrous materials. Magnaflux spotcheck are available in a variety of models to meet the needs of any NDT application. Magnaflux spotcheckers use magnetic particles to detect indications on the surface of ferrous materials. A magnetic field is generated by an electromagnet in the spotchecker, which attracts the particles to the surface of the material being tested. The particles are then visually inspected for indications, such as cracks, voids, or inclusions. Magnaflux spotcheckers are available in a variety of models, each designed for specific NDT applications. The basic model is the Spotchecker 1, which is ideal for general–purpose testing. The Spotchecker 2 is a more advanced model that offers increased sensitivity and additional features, such as a built–in light source. The Spotchecker 3 is the most advanced model, offering the highest sensitivity and a wide range of features, including a digital display and data storage. Magnaflux also offers a variety of accessories for its spotcheckers, including a carrying case, an AC adapter, and a variety of different sized magnets. Magnaflux spotcheckers are backed by a one–year warranty and are available through a network of authorized distributors. The process for applying Magnaflux Spotcheck is listed below: 1. Prepare the surface to be tested by cleaning it with a mild soap and water solution. 2. Apply the Magnaflux Spotcheck developer to the surface using a cotton swab orapplicator. 3. Allow the developer to dry for 1–2 minutes. 4. Inspect the surface for small black spots, which indicate the presence of a magnetic field.

What is Gear oil for chain lube and How to Apply I

Gear oil is a type of lubricant specifically designed for use in gearboxes and other mechanical parts that experience high levels of friction. Gear oil is usually thicker and heavier than other types of lubricants, and it contains special additives to protect against wear and tear. Gear oil chain lube is essential for keeping your gearbox running smoothly and reducing wear on the gears. Gear oil typically needs to be changed more frequently than other types of lubricants, so it’s important to check your owner’s manual for the recommended interval. You can usually tell when your gear oil needs to be changed because it will start to look dark and dirty. Gear oil is used for many applications including: 1. The gear oil helps to keep the chain lubricated and prevents it from rusting. 2. Reducing friction 3. Preventing wear 4. Gear oil for chain lube helps in extending the life of chains and gears by providing a lubricating barrier between the two surfaces. This prevents metal–on–metal contact, which can wear down both surfaces over time. How to apply gear oil for chain lube? You will want to apply the gear oil to the inside of the chain, using a clean cloth or brush to spread it evenly. Once the oil is applied, you will need to rotate the chain a few times to work it in and then wipe off any excess oil. There are a few reasons to buy gear oil from us for chain lube. First, gear oil is designed to lubricate gears, which are exposed to high levels of heat and friction. This makes it ideal for Gear oil chain lube, as it can provide a long–lasting lubrication that can withstand high levels of heat and friction. Additionally, gear oil is typically less expensive than other lubricants, making it a more affordable option for chain lube.

Applications for Molykote 111 compound

Applications for Molykote 111 compound Molykote 111 compound is a silicone–based grease that is used to lubricate and protect metal surfaces. It is used as a high–temperature, anti–friction coating for bearings, gears, and other moving parts. It is also used as a release agent for molds and dies. It is resistant to high temperatures and has excellent water repellence.It is NLGI Grade 2 and has a base oil viscosity of 150 SUS. It is also resistant to most acids and alkalis. The Molykote 111 compound has anticorrosion properties because it is a silicone–based lubricant. The silicone in the Molykote 111 compound forms a barrier on the surface of the metal, which prevents water and oxygen from reaching the metal and causing corrosion. It has Cold resistance properties because it is a silicone–based grease that can maintain its consistency and properties at low temperatures. It provides excellent dielectric strength properties. Some common applications for molykote 111 compound include: Lubricating moving parts in machines Preventing galling and seizing of threaded fasteners. Molykote 111 compound helps in Sealant for vacuum and pressure systems by providing a high–pressure seal that is resistant to wear and tear. It helps to lubricate, protect and seal rubber and plastic O–rings, gaskets and seals. The compound helps to prevent sticking, freezing and wear, and also provides corrosion protection. It helps in Chemical barrier coating by providing a barrier between the metal surface and the environment. This barrier prevents the metal from corroding and also provides resistance to chemicals. How to use Molykote 111 compound? Molykote 111 compound is a semi–fluid grease that is used to lubricate and protect metal surfaces. It can be applied by brush, roller, or spray. Our team will help to ensure the best material is delivered to your organization in specified time and proper support would be given at every point. We offer competitive pricing and can custom–formulate a molykote 111 compound to meet your specific needs. Our knowledgeable technical staff is available to answer any questions you may have about our products or their applications.

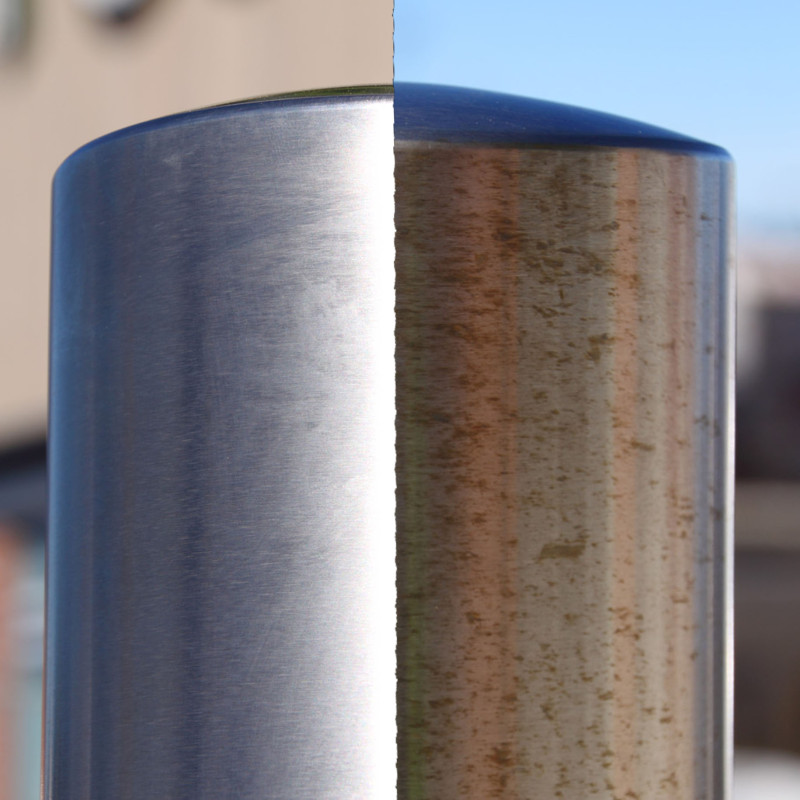

Remove rust from stainless steel

Remove rust from stainless steel–Technical Beacons The Stainless Steel Coating is a great product for protecting your stainless–steel appliances. It is easy to apply and has a long–lasting finish. This coating will help to resist fingerprints and smudges, and will also protect your stainless steel from rust and corrosion. This is a great product to use in your kitchen or bathroom, and will make cleaning your appliances much easier. Applications of Stainless Steel Coating: 1. It is used in the food and beverage industry for storage tanks, conveyors, and pipes. 2. Stainless steel is used in a wide variety of products in the pharmaceutical industry due to its ability to resist corrosion and its non–reactive surface. Some of the products that stainless steel is used in include: Pharmaceutical equipment, Storage tanks, Piping, Fittings, Vessels, Heat exchangers. 3. Stainless steel coating is used in cosmetics industry as a protective coating on cosmetic products. This coating helps to prevent the products from being damaged by the environment and also makes them more resistant to bacteria and other microorganisms. 4. There are many uses for stainless steel in the chemical industry. One of the most common is in storage tanks. Stainless steel tanks can be used to store a variety of chemicals and can withstand the corrosive nature of many of these substances. How to apply Stainless Steel Coating? Stainless steel coating can be applied in a few different ways. The most common method is to spray it on with a pump sprayer. You can also apply it with a brush or roller. We offer high–quality Stainless Steel Coating at competitive prices. Our products are backed by a 100% satisfaction guarantee, so you can buy with confidence. Our team of experts will help you in every step of the transaction and also help in additional application usage.

Rust converter paint

Rust converter paint is a type of paint that helps to convert rust into a more stable compound. It is typically used on metal surfaces that are exposed to the elements, such as fences, gates, and outdoor furniture. Rust converter paint typically contains two main ingredients: an acidic compound and a polymer. The acidic compound helps to break down the rust, while the polymer helps to bind the rust together and prevent it from flaking off. Rust converter paint is available in both aerosolized and liquid form. There is no set price for rust converter paint, as the price will vary depending on the brand, type, and quality of the paint. Rust converter paint should be kept in a cool, dark place away from direct sunlight. There are both pros and cons to using rust converter paint. Some of the pros include that it is relatively inexpensive, it is easy to apply, and it does a good job of stopping rust from spreading. Some of the cons include that it does not always adhere well to rusty surfaces, it can be difficult to remove if you decide you do not like it, and it does not always provide a long–lasting finish. Rust converter is a paint–like product that is applied to rusted metal to stop the rusting process and protect the metal from further corrosion. It is important to properly prepare the surface before applying rust converter. The surface must be clean and free of any loose rust, paint, or other debris. Once the surface is prepared, the rust converter can be applied with a brush, roller, or sprayer.

GREASE TYPES AND ITS CHARACTERISTICS

GREASE TYPES AND ITS CHARACTERISTICS Aluminum Complex Grease Has Good high fever faculties, with a falling point approximately 500°F, Great water tolerance, good shear stability, and reacts nicely to additive treatments that enhance performance capabilities, such as oxidation and rust inhibition. Often utilized in digesting food machines Matrix Foodmax Grease ASP 2 is an aluminum complex grease designed for the lubrication of almost any type of application which requires a food grade lubricant. Foodmax Grease ASP 2 is formulated with a complex soap, synthetic base oils, additive package and solid lubricants. Thanks to the superior resistance to water ASP 2 is very suitable for the lubrication of chains operated in very wet conditions such as food conveyor chains. Bentone (Clay) Grease Bentonite clay grease is medicated with a polar activator which provides an electrical charge to the clay particles, thus aligning them to keep the lubricating oil in suspension in a non-soap thickened, grease structure. Perhaps not quite harmonious with different greases, since the electrical charge may be destroyed and soften the dirt outside performance limits. Such a product is often referred to as a No-Melt grease. Has good water resistance, very low temperature pumpability and exceptionally high temperature applications in which a non-melting grease is demanded, the clay structure can assist in assembling a self-forming oil seal where bearing seals are hopeless to keep such as in wheel bearings onto temperature kiln cars. MOLYKOTE 41 High Temp Grease • Does not melt, even at high temperatures • Superior thermal stability • Superior oxidation resistance • Water-resistant Composition • Silicone oil • Carbon black • Corrosion inhibitor Calcium Grease Calcium Grease One of Certainly one of the first kinds of dirt manufactured. Used today mainly since they Are moderately priced. Manufactured by utilizing hydrated lime and a fatty material. Magnesium must be Utilized at Less temperature surroundings, because They’re restricted by approximately 150°F. Higher temperatures can alter the Grease structure. Has very good water tolerance. FUCHS-Renax MPG Grease RENAX MPG is a premium quality lithium-calcium mixed base grease based on a lithium-calcium hydroxy stearate soap. Because of its chemical properties and its additive package, RENAX MPG is suitable for a wide range of applications under severe operating conditions. Lithium (12-Hydroxy Stearate) Grease A Multipurpose grease type dirt having a buttery feel and falling point above 350°F. Could be utilized with intermittent temperatures as much as 300°F. Lithium grease has Great resistance to breakdown and water, or burning off, by workingout. Pumpability is just really actually a really good characteristic for this kind of grease. The expression Multi-Purpose Grease is utilized because they blend, in One Solution, Desirable features normally utilized in all several services and products. Nearly 60 percent of the entire grease market is fulfilled via such a grease. ASV ML–2 EP2 Grease • Extremely wide service temperature range of -25°C to +120°C • Reduces friction and wear • Low evaporation rate increases relubrication intervals • High load carrying capacity • Highly resistant to hot or cold water and water washout • Offers good surface protection and corrosion inhibiting properties • Good resistance to oxidation • Can be dispensed via centralized lubrication systems Lithium Complex Grease A fresh kind of dirt, revealing a number of the same traits as the very simple lithium greases, together with improved performance in the area of high temperature, high speed bearing life. Dropping point is approximately 500°F. SKF LGMT 3/1 GREASE General purpose industrial and automotive NLGI 3 grease SKF LGMT 3 is mineral oil based, lithium soap thickened grease. This premium quality, general purpose grease is suitable for a wide range of industrial and automotive applications requiring stiff grease Excellent rust inhibiting properties High oxidation stability within its recommended temperature range Polyurea Grease A Grease of fairly recent development that does not make work with of a conventional soap thickener. This type of grease Features a high dropping point, approximately 470°F, has an ashless structure, superb water resistance, pumpability and superb temperature posture. Usually Utilized in electrical motors, Alternators and from food machinery. A few Polyurea greases Are Extremely shear Sensitive, that is, they are going to soften in dispensing and harden in the bearings. Lighter consistency greases can give better operation under these conditions. SKF LGHP 2/1 Grease SKF LGHP 2 is a premium quality mineral oil-based grease, using a modern Polyurea thickener. It is suitable for electric motors and similar applications. • Extremely long life at high temperatures • Wide temperature range • Excellent corrosion protection • High thermal and mechanical stability • Good start-up performance at low temperatures • Compatibility with common polyurea and lithium thickened greases Grease Compatibility After two greases are mixed, the resultant blend frequently displays properties and performance characteristics that are clearly inferior to those of grease by itself. For this reason, it is best to exercise caution in switching between forms of grease that might have compatibility issues. The system ought to be cleaned of previous dirt when creating a switch between grease types. When it’s not possible to eliminate previous dirt type from the bearings, dirt more often until all traces of earlier grease are flushed from this bearing.

What is Epoxy putty stick?

What is Epoxy putty stick? Epoxy Putty Stick, Also Known as metal plasticine or adhesive Metal, is a highly strongly adhering plasticine based on epoxy resin. Epoxy Putty Stick is dependent on exactly the exact two-component system as smoking. The curing reaction is, thus, started when the two components resin and hardener are mixed together. However, this technique doesn’t require any effort on the part of the user, as the adhesive metal is supplied at a practical roll. Mixing is done solely by massaging the chemical. With this particular stuff, minor damage could be permanently adjusted. Epoxy Putty Stick does not obtain its reputation for nothing: it can be mimicked and is hence unbelievably flexible; once hardened, it’s about as hard as steel. It even sets on damp surfaces or underwater. The curing process takes just several minutes for many products. In case You have repaired cracks or damaged areas together with the help of the metal Plasticine, you can further process paint and sand them. Since Epoxy Putty Stick could be applied to various surfaces, so It’s suitable for a Wide Variety of work. It provides many advantages not only for industrial processing but also for the do-it-yourselfer. WEICON Repair Stick Steel Fast cure Steel-filled NSF approval, can be used in drinking water areas It is particularly suited for the fast and high-strength repair and bonding of metal parts and for the patching and sealing of cracks, holes, and leaks in machine parts, tanks and pipelines, containers, pumps and housings, balcony railings, banisters, and torn-out threads. The WEICON Repair Stick Steel can be used in machine and system construction, in tank construction and apparatus engineering, in the foods, cosmetic and pharmaceutical industries and in many other applications. WEICON Repair Stick Stainless Steel Non-corrosive, fast cure Stainless steel-filled NSF approval, can be used in drinking water areas For non-corrosive repair and reconditioning of stainless steel and other rustproof metals, such as those in tanks and containers, filling and packing machines, pipes, lines, pumps and housings. The WEICON Repair Stick Stainless Steel can be used in tank construction and apparatus engineering, in the foods, cosmetic and pharmaceutical industries and in many other applications. WEICON Repair Stick Aluminum non-rusting aluminum-filled For the quick and nonrusting repair and bonding of metal parts. For the repair of cracks, holes and leaks in car bodies, gearboxes and tanks, window frames and profiles, and boats and models. The WEICON Repair Stick Aluminum can be used in machine and system construction, in the automotive industry, in gear construction, window construction, model building and many other applications. WEICON Repair Stick Aqua For underwater applications Ceramic-filled Ideal for quick repairs on damp and wet surfaces and for underwater applications. For the repair and sealing of cracks, holes, and leaks in petrol and water tanks, radiators, electrical switchboards, sanitary installations and swimming pools. The WEICON Repair Stick Aqua can be used in sanitary and heating system construction, electrical equipment, the maritime sector and many additional industrial applications. WEICON Repair Stick Copper Extremely fast cure Copper-filled NSF approval, can be used in drinking water areas The WEICON Repair Stick Copper is suited for the very quick repair (processing time: 3 min.) of cracks and leaks even on damp and wet surfaces such as pipes, pipe bends, fittings, flanges, copper gutters, sheets, water heaters, water tanks, hot, cold-water lines, freezer and air conditioning systems. The WEICON Repair Stick Copper can be used in tank construction and apparatus engineering, in the foods, cosmetic and pharmaceutical industries and in many other applications. Weicon-Repair Stick Titanium Wear resistant Titanium-filled High temperature resistant up to +280°C (+536°F) (briefly up to +300°C/+572°F) It is suited for the permanent and wear resistant repair and bonding of metal parts such as tanks and pipelines, aluminum, light metal and injection moulded parts, shafts and slide bearings, pumps and housings and torn-out threads. The WEICON Repair Stick Titanium can be used in machine and system construction, tank construction and apparatus engineering, and in many other industrial applications. J-B Weld Steel Stik Steel Reinforced Epoxy Putty Stick Steel Stik is a hand-mixable, steel-reinforced, non-rusting epoxy putty that quickly repairs or rebuilds anything made of metal. After mixing, it forms an industrial-strength polymer compound that can be molded into shapes or used to build up, patch and repair steel components. Steel Stik sets in 3-5 minutes and after 60 minutes, can be drilled, tapped, machined, ground, filed and painted. SteelStik cures to a dark grey color, is rated at a tensile strength of 900 PSI and will withstand temperatures up to 300ºF. J-B Weld HIGHHEAT EPOXY PUTTY High Heat is a hand mixable epoxy putty stick specifically formulated to bond and repair materials that will be exposed to high temperatures in automotive and industrial maintenance applications. It cures to a tough, hard bond with little to no shrinkage. This industrial-strength product outperforms conventional epoxy putties at high temperatures and sets in 1 hour at room temperature. After 8 hours, it can be drilled, tapped, machined, ground, filed and painted. High Heat is rated at a tensile strength of 800 PSI and cures to a machine grey in color. It is able to withstand continuous heat exposure of 450ºF and intermittent heat exposure to 500ºF J-B WELD WATER WELD EPOXY PUTTY Water Weld will plug or seal leaks and patch holes and cracks in almost anything. Ideal for repairing plumbing, fuel tanks, tub and shower, drains, pool and spa, boats and potable water tanks; setup occurs even under water. After curing, it can be drilled, tapped, filed, sanded and painted. WaterWeld has a set time of 15-25 minutes and sets hard in one hour. WaterWeld cures to an off-white color, is rated at a tensile strength of 1300 PSI and will withstand temperatures up to 300ºF. The Best Way to Make Use of epoxy putty The greatest selling point of epoxy putty is how easy it’s to utilize. Once you have mixed it by hand, you only apply it into the cloth or area requiring repair. It’s soft enough to shove into holes and cracks, fixing leaking pipes and creating watertight seals around drains, and other plumbing parts. Repairing cracked and cracked concrete and masonry is equally straightforward: simply mould the kneaded putty into place. For example, an adhesive, it can be utilized to stick 1 material into another in precisely the same manner that you’ll employ blue tac. Once the putty gets cured, you’ll be able to do anything for it. Paint it, drill it, and saw it. It won’t pull or pull off. Once you’ve finished carrying out the repair job or task in hand, then it is possible to keep the rest of the putty. All epoxy putties will stay fresh if kept tightly sealed within their original packaging, ready and waiting to serve you again in the future.

Anti-Seize Compound

Anti-Seize Compound disulphide that ensures performance enhancement of the anti-seize compound. The one ideal usage of it is in high temperatures which covers areas such as furnaces. It is a known fact that the product needs to be used in the perfect amount, as both over application and under application can make a mess and not give the desired results. While one wastes the product, the other reduces its effectiveness. This is the kind of product that comes in handy at the time where an area is corrosive. Additionally, it also improves the gasket performance along with which it helps with the removal process of a gasket. They are also good at preventing thread galling during installations, which also goes on to save one the additional costs that the problem might give way to. Features and Benefits A product as good as this has a lot of features and benefits that work in its favor. Those are: It helps in preventing seizure, galling and corrosion. One can rely on it to be highly resistant to salt water environments. It has a lead-free formulation It makes for an excellent way to resist water. The solution even works when the surface is submerged. The product can ensure a temperature range of -50ºC to +1100ºC The anti-seize compound is made for general purposes. However, the wide range of features of this product make it a very reliable one to be used on many surfaces. Its perfect metal bonding and good lubricity ensure that the product works its magic on the surfaces that it is used in. Extremely wide service temperature range of -30°C to +1100°C Makes disassembly easy and non-destructive even after long operational periods at high temperatures and adverse working environments High load withstanding capacity Creates an effective matrix between mating surfaces to prevent metal-to-metal contact Protects surface from wear and friction.