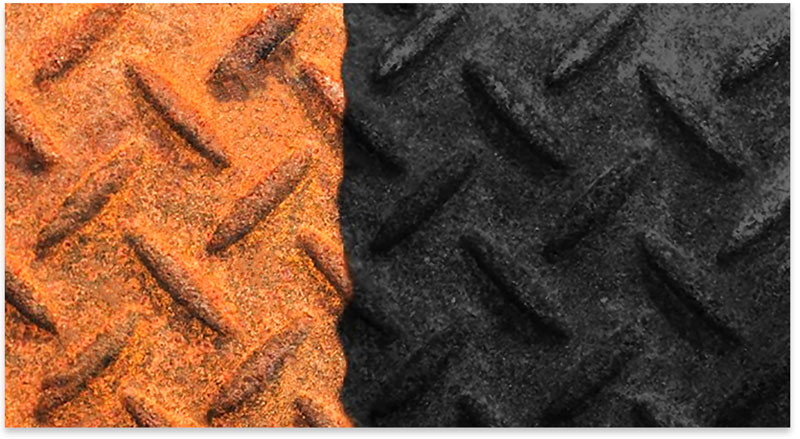

Rust Converter

Choose the Best Rust Converter

The best way to turn rust

into a substance that appears paintable once again is to use rust converters. You

must choose the Best Rust converter that can function as both rust stain

removal and stoppers since they can transform the rusted surface into a

material that can be polished.

When sheet metal is confronted with moisture, rust develops, and this rust can

make a metal object exceedingly fragile. There are various varieties of rust,

some of which seem relatively simple to repair. On metal, however, there can be

significant rust that affects the performance of the vehicle.

However, there are other ways to get rid of rust, as most people use wire

brushes and sandpaper. But rust cleaners seem to work quite well. A rust

remover is another well-known product available on the market that efficiently

separates corrosion from the surface of the metal.

Different Rust Converters Rust converters come in three

different basic types:

Liquid: The most prevalent kind of rust

converter is liquid. Whatever material

thicknesses are utilized, the application technique is usually the same. You

can brush on, submerge in, or use a sprayer to apply the chemical after some

preliminary work. You will have to select the finest and simplest way based on

your project.

Gel: A

Rust Converter is also accessible in gel form. You cannot use them with

sprayers. They are preferable to liquids since they don’t drip when applied

firmly. The gel should generally be painted or spread onto the surface of the

metal, then let dry.

Spray: Although

some rust-removing solutions are fluid removers that may be applied with a

spray gun, others are aerosol sprays. This approach is usually faster to use

when compared to other ones. Spray cans are supplied in small quantities, and

it might be hard to use them for extensive restoration tasks.

A single water-based active chemical (liquid) called “Rust Converter” combines with adherent rust on metal surfaces to create a durable protective coating. The steel won’t rust any more thanks to this coating.

Tannic acid and an organic polymer are the two active elements in rust converters, which are waterbased primers. Rust is made of iron oxide, which tannic acid combines with chemically to create iron tannate, a durable substance that is dark in colour. Tannins are a class of naturally occurring substances that can be obtained from fruits, trees, and grasses and are soluble in water and alcohol.

2-Butoxyethanol, the second active component, is an organic polymer that acts as a primer layer of protection. Rust is transformed into a durable black protective polymeric covering by the total chemical process, which makes it a superb primer for both oil- and epoxy-based paints.

Instructions for Use:

1. When dealing with corroded mild steel or carbon steel surfaces, start by mechanically chipping, wire brushing, or otherwise removing the loose rust scales.

2. Make sure there is no oil, grease, paint, or other material on the area that will be handled with Rust Converter. Use a brush, spray, or dip to effectively apply Rust Converter after that.

3. To guarantee that the Rust Converter reacts completely with the rust, leave the area alone for at least 24 to 48 hours. The surface is then ready for any kind of subsequent coat.Areas of Typical Application

Drilling rigs, chemical process equipment, and storage tanks, tube and pipe stock, conveyors, cranes, bridges, pipelines, overhead water tanks, heavy structural steel tankers (on land and at sea), concrete reinforcements, automobile dickeys, etc., and essentially all kinds of industries where the issue of iron rust is available. Coverage and Enduring:

Rust Converter has a 25–30 square meter coverage area per litre. Whenever kept in a plastic container that is tightly sealed, it has an endless shelf life. Rust contained in used Rust Converter might cause a chemical reaction in unused Rust Converter, thus never combine used and unused Rust Converter together.

- Removes Rust Quickly. No heavy wire brushing or sand blasting required.

- Safe Acid Technology. Not harmful to skin.

- Non-Corrosive. Safe to use on all metals

- Non-Flammable.

- No special equipment is necessary. Parts are simply submerged in the solution.

- No heavy fumes or bad odors.

- Zero VOC.